40 best way to label warehouse racking

Warehouse Rack Labeling and Signage - D1SW DeltaOne uses a simple and economical way of barcoding bin and rack locations using color-coded labels. Our years of experience have taught us the best ways to print and apply location labels and we can help you accomplish this vital task. It is critical to have every location clearly identified with 100% accuracy. PDF A Guide to Warehouse Racking and Storage Types - Cen Global® Example Naming Structures Terminology Warehouse - The warehouse code, eg 03, to identify it is a warehouse 3 location Aisle - An aisle consists of all locations within a set of racking at its widest point, from ground to roof, end to end. Row - A row consists of the vertical locations from ground to roof within an aisle Level - The horizontal locations from end to end on one level within ...

Best Practices for Warehouse Labeling - Supply Chain & Logistics Basics Some of the top factors to consider when labeling your warehouse include barcode scheme, label materials, label placement and supporting technologies. Here we will look into each topic more in depth. First, identifying the barcode scheme that works for all parties involved is standard - both the GS1 and UPC schemas are used frequently.

Best way to label warehouse racking

How to Label a Warehouse Rack - Camcode But, even if you are a small operation that is using bare-bones racking solutions, like two-shelf pallets, you will still want to label your racks from the ground up, by giving the lowest row the name of '01'. The second row will be labeled as '02' - and so on, and so on. › blog › warehouse-operations-bestWarehouse Operations Best Practices: 55 Awesome Tips and ... Feb 15, 2022 · – Nancy Master, Identifying Warehouse Management Best Practices, RFgen; Twitter: @RFgenSoftware 47. SKU profiling can facilitate profitability. “Understanding how every SKU carried in your distribution center (DC) can – and should – contribute to your company’s bottom line – is the best way to design and run DC operations. Warehouse Locations and Bin Labeling: Best Practices and Tips It is best practice that when setting up alphanumeric locations to use a zero in all numbers less than ten (i.e. 01, 02, 03, etc.). This will allow the system to accurately read the locations alphanumerically. Be consistent. There's nothing that will screw up your system and your employees faster than having an inconsistent method of labeling.

Best way to label warehouse racking. Tips for Effective Warehouse Numbering Schemes - ID Label Inc. Warehouse Zone. Zone markers are used to identify a set of locations within a warehouse. For example, zones might be used for bulk storage, case storage, dry goods, freezer inventory, receiving, staging, etc. Aisles. One way to number warehouse aisle signs for growth is to start with aisle "10" or "BA," which allows for flexibility. Warehouse Rack Labels and Inventory Labeling Solutions - Camcode For example, Camcode's cold storage rack labels and cold storage rack placards, designed for use in environments down to -20°F and -40°F, respectively, provide an ideal warehouse rack labeling solution for warehouses dealing with perishables or frozen goods. Get a Free Warehouse Label and Sign Evaluation Kit Warehouse Rack and Beam Labels - Labelmatch Labelmatch Warehouse gives you the backing of one of the top experts in the industry. We can design, test, produce and install your warehouse signs and labels. Use our best-practice understanding of warehouse operations, barcode scanning and label production. Our vast experience speeds the process and eliminates potential mistakes. Warehouse Labeling | Barcoding There are several types of labels, and the one that's right for your warehouse and its assets will depend on your warehouse and its assets, and your specific goals. Magnetic: Magnetic labels are the best choice when the warehouse configurations change frequently, as they're easy to remove and reaffix to another rack

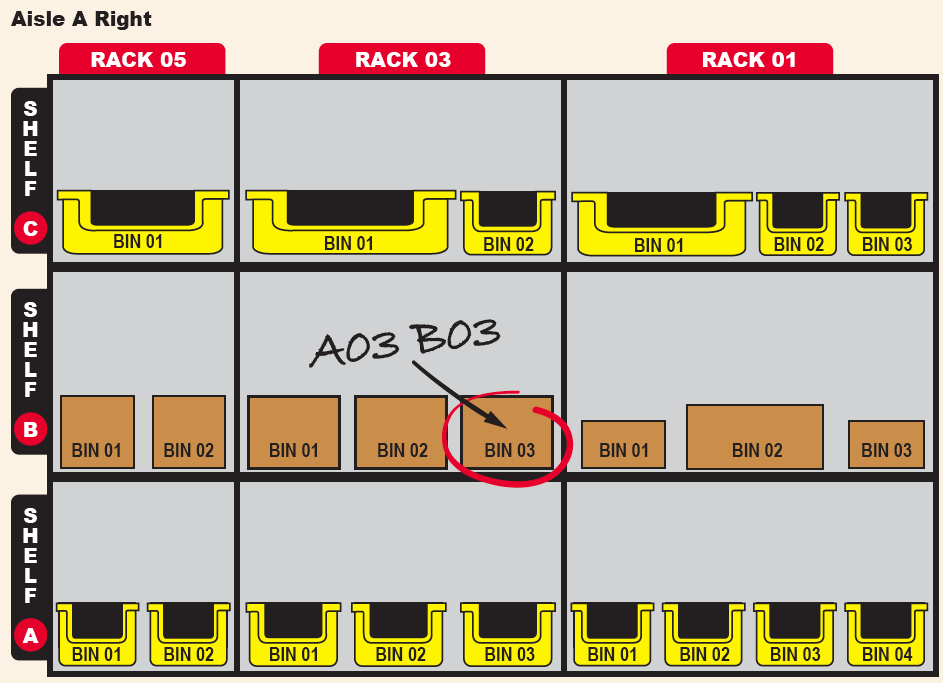

New Warehouse Design? Tips on How to Label Warehouse Racking - LIDD With any method, the key factor is to stay consistent and flexible. To do that, we typically recommend a matrix style numbering system that consists of 3 or 4 components: aisle, rack and/or position, and level. A combination of letters and numbers can be used to make the slot numbers easier to read. AISLES shelving.companyBolt On Shelving Manufacturers In Johannesburg | Shelving ... Label Holders. Speak to us about our offers on self-adhesive label holders for your storage and shelving systems. Packaging Consumables. From bubble and pallet wrap to packaging tape and more, we offer a complete range of specialised packaging consumables. BOLT ON SHELVING SALE. Shelving bay 1800mm (H) x 305mm (D) x 914mm Wide; 5 level galvanised Warehouse Racking Safety Guidelines: Satisfying OSHA - iGPS The iGPS plastic pallet is able to hold heavier static and dynamic loads than a reusable wood block pallet and is equipped with GS1-compliant tracking. To get started with a durable, heavy-duty plastic pallet, give our team a call at 1-800-884-0225, email a specialist at switch@igps.net, or visit our contact page. By iGPS What are the best way to label warehouse racks? The best ways to label warehouse racking lies in the clarity of the location label. Location labels are what mark the place of an item that can be found by scanning a barcode, which then will give the scanner the precise location of the product to go find in the warehouse. Creating an Efficient System

Creating a warehouse location numbering scheme? Read this first! Level or shelf - should be assigned and address from 1 to 9 ascending from the floor. If you have more than 9 levels you should start with 01. Position - assign numbers to each position ascending from 1 to 9, from left to right as you face the rack. Here's an example of a location label where the format is Aisle - Rack - Level - Position. Shelving | Commercial Storage Solutions | STACK-iT Perfect for identifying stock, simple peel the magni-label off and relocate it whenever products change. Moulding Racks These racks are an innovative and space efficient solution for storing all your aluminium and pipe lengths. Shelving Safety Tips to Keep your Warehouse OSHA Approved 4. Enforce Weight Limits. Putting too much weight on shelves is a sure way to set your warehouse up for a catastrophe. Even if the shelf appears to be holding the weight without visible damage, the additional strain put on the shelving and supports makes the whole structure vulnerable to sudden collapse. How to Barcode your Warehouse - DataNinja If your warehouse is sectioned for functional reasons or if you have multiple warehouses we recommend you add a single distinguishing letter in front of the X-Y-Z coding scheme. If you have racking with rollers so each isle-bin location is 2 pallets deep we recommend that you have one location barcode that represents both pallet locations.

Naming and labelling warehouse bins and shelves - Datalinx A suggested naming of the racks in the aisles is shown below. This would be suitable for guiding picking down one side of the rack and then back up the other side. Fig 1. However, if the 'walking' is to be done from 'side to side' in a 'work' aisle, the racks would be labelled as in the following example (Fig 2). Fig 2.

Signs, Barcode Labels & Line Striping A world renowned beverage company, focused on mass output with unrivaled performance found ASG Services, the leading provider of warehouse identification and marking products. They needed a company to help with the complex delivery of floor striping, warehouse barcode signs and rack labels, all installed within a specific window.

How to Label a Warehouse - Express Corp Shelves: The common and preferred method of warehouse shelf labeling is by section. Each shelf within a unit should count up from one and continue numerically until you reach the end of a shelf aisles. Depending on the warehouse, you could decide to put your shelf value in the last position of your location code.

Rack Labeling | Creative Safety Supply If you have more than one level of racks, it's recommended to label from the ground up and start by giving the row closest to the ground a label such as "01". The second row can be "02", and so on. Using double digits accommodates the fact that you may add more levels in the future and if so, you won't need to make changes to your system.

5 Keys to Warehouse Rack Labeling - Express Corp 3) Grid or serpentine layout - When envisioning a warehouse and making plans to use warehouse labels most effectively with racks, it is essential to decide how the layout will be done. When a warehouse has to address the issue of picking and packing orders strategically, the layout of the racks is best done in the curving style known as serpentine.

shelving.company › RackingIndustrial and Commercial Racking Systems In ... - Econorack Label holders are a clear plastic strip that holds and displays labels or barcodes. The label holders come with double sided tape fixed to the back so you can easily stick the labels where needed. These are ideal for shelving and racking applications. Supplied with a clear front on a white background. Various sizes available: 25mm High x 1000mm ...

How To Make Good Labels For Inventory Locations Your labels should start with the zone abbreviation (if you use zones), the section letter (if you use sections), and then descend from 1 - 10 or A-Z from the highest point to the floor. If you have two locations side by side on a shelf, consider ending one with "L" and the other with "R" (for "left" and "right").

Signs, Document Holders, Warehouse Labels, Floor ... The racksack is a range of warehouse recycling and segregation sacks to help manage your warehouse and packaging waste, etc. available off the shelf in 14 different designs and 2 colour choices. Alternatively bespoke designs and logos can be printed – please enquire. View 12 products

What Are The Ways to Label Bin and Rack Locations? It woud be best to map and segment your warehouse and assign specific location names for each of these segments Establish a Bin and Rack Numbering and Labeling Scheme Each aisle, rack, shelf or position should have a specific location code and should be properly labeled based on this location code.

Post a Comment for "40 best way to label warehouse racking"